Exemplars

Principles in action

Alcoa Corporation

How an aluminum company became the safest company in the world

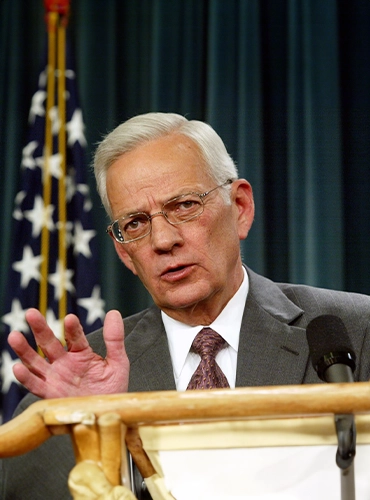

Under the leadership of Paul O’Neill, Alcoa, a multi-billion-dollar aluminum company, transformed into the safest company in the world. O’Neill prioritized safety above all other goals, strategies, and budgets, firmly believing that people were the company’s most valuable resource.

He implemented a policy where every risk and injury had to be reported, mitigated, investigated, and resolved within a 24-48 hour window. To support this, a global information system was created, allowing incidents to be immediately reported an7d accessed worldwide, enabling proactive corrective measures.

- Am I treated with dignity and respect by everyone I encounter without respect to gender, or nationality, race, educational attainment, rank, or any other distinguishing feature?

- Am I given the things I need – training, education, tools, resources, encouragement, etc. – to make a contribution to the organization that also adds meaning to my life?

- Am I recognized in a meaningful, sincere way for that contribution by someone whose opinion matters to me?

O’Neill’s commitment to safety led to superior results across all areas of operations, decoupling Alcoa’s profits from volatile aluminum prices. By adopting the principles of the Toyota Production System as the company’s management system, O’Neill fostered a culture of continuous improvement that sustained safety and operational achievements long after his retirement.

During Paul O’Neill’s tenure from 1987 to 2000, Alcoa experienced significant improvements across multiple key metrics. The company’s earnings surged from $200 million to $1.484 billion, and its market capitalization increased dramatically from $7.7 billion to over $30 billion. Alcoa’s workforce also expanded substantially, growing from 55,000 to 142,000 employees. In addition to these financial and operational gains, Alcoa achieved $1.1 billion in cost savings over three years through its ABS (Alcoa Business System) initiative.

Notably, the company’s profits became more independent offluctuating commodity prices, further stabilizing its financialperformance. These outcomes underscore the transformativeimpact of O’Neill’s leadership on Alcoa’s growth andefficiency.

Presbyterian Senior Care Network

Enriching the lives of the elderly

Presbyterian SeniorCare Network, a senior living organization in Western Pennsylvania, embraced the principles of the Toyota Production System to transform the aging experience for its residents. Committed to enriching lives through person centered care, they are applying continuous improvement methodologies to create more efficient, compassionate, and responsive services.

By focusing on the individual needs and preferences of each resident, they are streamlining processes, reducing waste, and enhancing the quality of care. Whether in assisted living or skilled nursing, the application of these principles ensures that each resident receives the best possible care in an environment designed to support their well-being and dignity.

This commitment to person-centered service improves operational efficiency and creates a more fulfilling and comfortable living experience for their aging community.

Community Church Food Ministry

Feeding those in need in times of crisis

In 2020, when COVID-19 disrupted daily life, the Community Church Food Ministry rose to the challenge, filling the gap for inner-city children in need. Initially, they provided drive-through free warm lunches, then expanded to home deliveries through the Urban Impact Foundation. As demand grew, so did their efforts, doubling their service to include a warm lunch and breakfast for the next day, reaching over 1,000 meals per day.

This incredible feat was not difficult for them to achieve. Why? Because their system of Continuous Flow is both scalable and robust, capable of serving from one person to 10,000 without missing a beat. Their commitment reflects their mission: “God’s Chosen People, Serving God’s Food, to God’s Family.

The key takeaway from this case study is that these principles aren’t limited to large-scale operations. They can be applied to your life, your family, your church, your work, or your neighborhood—just as they were used to feed those in need.